SHX Series Circulating Fluidized Bed Boiler

- Boiler capacity :6~50t/h ¦ 14~64MW ¦ 20-75 t/h

- Pressure :3.82Mpa-5.29Mpa | 38.2bar-52.9bar

- Fuel :Bituminous coal, anthracite, lean coal and lignite coal, coal gangue, slag,etc.

- Application : Power Plant, central heating,chemical industry etc

- Brief Intro :SHX series boiler is a large capacity boiler, the new type boiler makes big breakthrough on the technology of cyclone fluid combustion, cyclone separation structure & parametric design, and loop seal device.

Email: [email protected]

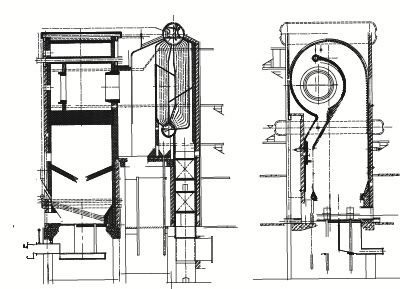

The new type double whirlpool circulating fluid bed boiler with low speed is a new generation CFB boiler. It is consist of combustion chamber, separator, fly ash circulating system, superheater, convection bank, economizer, and air preheater. The boiler inherits the original technology advantages, at the same time, makes big breakthrough on the technology of cyclone fluid combustion, cyclone separation structure & parametric design, and loop seal device. The thermal efficiency is about 5% higher than the other CFB boilers.

The new type double whirlpool circulating fluid bed boiler with low speed is a new generation CFB boiler. It is consist of combustion chamber, separator, fly ash circulating system, superheater, convection bank, economizer, and air preheater. The boiler inherits the original technology advantages, at the same time, makes big breakthrough on the technology of cyclone fluid combustion, cyclone separation structure & parametric design, and loop seal device. The thermal efficiency is about 5% higher than the other CFB boilers.

Technical Advantages

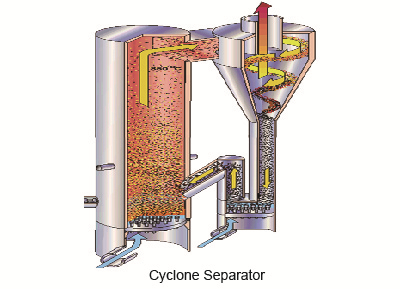

1. Double Cyclone Separator

After separated by the second cyclone, the fuel powder particles return to furnace for circulating combustion through the separate loop seal. The diameter of particles could be cut into 10μ by separator, improve the combustion efficiency.

2. Parametrization Design on Separator

Using the results of latest experiment, redesign the parameter of separator, optimize the line and size of cyclone separator, the separate efficiency improved greatly.

3. Bubbling Fluid Loop Seal Technology

Using the hood bubbling fluid integrate loop seal device, achieve the situation of bubbling fluid. It has the advantages of material feed steadily, convenient control, and avoid coking.

4. Cyclone Combustion Technology

Arrange cyclone combustion device in furnace, achieves cyclone fluidized circulating combustion, improve combustion efficiency.

5. Membrane water wall

The furnace, separator and loop seal device adopts membrane water wall, prevents the low efficiency caused by air leakage, low heat loss.

6. Anti wear design

The buried pipe adopts anti-wear steel with the special size and angle, and reduce the fluidization velocity, to reduce the wear. The high temperature resistant material is deposited on the water cooling wall of the separator, avoiding the abrasion of membrane wall.

7. Environment Protection

The product uses low-temperature combustion technology, reduce the generation of noxious gas, also, the limestone could be added to the furnace for desulfuration, meet the requirement of environmental protection.

Parameter

Steam Boiler

| Model | Steam Capacity (t/h) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) | Design Efficiency (%) | Body Dimension (mm) |

| SHX6-1.25-A II | 6 | 1.25 | 194 | 105 | ≥86 | 9795×7160×13950 |

| SHX8-1.25-A II | 8 | 1.25 | 194 | 105 | ≥86 | 10295×7160×13950 |

| SHX10-1.25-A II | 10 | 1.25 | 194 | 105 | ≥86 | 10795×7160×13950 |

| SHX15-1.25-W+Slag | 15 | 1.25 | 194 | 105 | ≥86 | 10315×8270×14810 |

| SHX20-1.25-AII+Slag | 20 | 1.25 | 194 | 105 | ≥86 | 11565×8570×15500 |

| SHX25-1.25-A II+Slag | 25 | 1.25 | 194 | 105 | ≥86 | 12660×8810×17000 |

| SHX35-1.25-W+Slag | 35 | 1.25 | 194 | 105 | ≥86 | 13350×9880×15800 |

| SHX40-1.25-W+Slag | 40 | 1.25 | 194 | 105 | ≥86 | 14430×9700×15000 |

| SHX50-1.25-A II+Slag | 50 | 1.25 | 194 | 105 | ≥86 | 14430×9630×15765 |

|

Note:1.Parameter is for reference only,we can design the new products based on your requirement. 2. Available fuel: anthracite,bitumite, lignite, lean coal,coal gangue,blended fuel of bitumite and chain slag. |

||||||

Hot Water Boiler

| Model | RatedPower (MW) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) | Design Efficiency (%) | Body Dimension (mm) |

| QXX14-1.25/95/70-A II | 14 | 1.25 | 95 | 70 | ≥86 | 11565×8570×15500 |

| QXX29-1.25/130/70-W | 29 | 1.25 | 130 | 70 | ≥86 | 12930×8280×19800 |

| QXX29-1.6/150/90-H | 29 | 1.6 | 150 | 90 | ≥86 | 12930×8280×19800 |

| QXX46-1.6/130/70-A | 46 | 1.6 | 130 | 70 | ≥86 | 15530×11080×21300 |

| QXX58-1.6/130/70-A | 58 | 1.6 | 130 | 70 | ≥86 | 16240×10600×23500 |

| QXX64-1.6/130/70-A | 64 | 1.6 | 130 | 70 | ≥86% | 17500×11000×24500 |

|

Note: 1.Parameter is for reference only,we can design the new products based on your requirement. 2. Available fuel: anthracite,bitumite,lignite, lean coal,coal gangue,blended fuel of bitumite and chain slag. |

||||||

Power Plant Boiler

| Model | Rated Evaporation (t/h) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) | Design Efficiency (%) |

Body Dimension (mm) |

| ZDG-25/3.82-M | 25 | 3.82 | 450 | 105 | ≥ 86 | 12650×8530×13200 |

| ZDG-35/5.29-Q | 35 | 5.29 | 450 | 150 | ≥ 86 | 13350×9880×15800 |

| ZDG-40/3.82-M | 40 | 3.82 | 450 | 105 | ≥ 86 | 14530×10280×18800 |

| ZDG-75/3.82-M | 75 | 3.82 | 450 | 150 | ≥ 86 | 16240×10600×33500 |

| ZDG-130/3.82-M | 130 | 3.82 | 450 | 150 | ≥ 86 | 21060×14400×40650 |

| ZDG - 220/9.8 - M | 220 | 9.8 | 540 | 215 | ≥ 86 | 25540×23420×47800 |

|

Note: 1. Parameter is for reference only, we can design the new products based on your requirement. 2. Available fuel: anthracite, bitumite, Lignite, lean coal, coal gangue, and chain slag, etc. |

||||||

1. Double Cyclone Separator

After separated by the second cyclone, the fuel powder particles return to furnace for circulating combustion through the separate loop seal. The diameter of particles could be cut into 10μ by separator, improve the combustion efficiency.

2. Parametrization Design on Separator

Using the results of latest experiment, redesign the parameter of separator, optimize the line and size of cyclone separator, the separate efficiency improved greatly.

3. Bubbling Fluid Loop Seal Technology

Using the hood bubbling fluid integrate loop seal device, achieve the situation of bubbling fluid. It has the advantages of material feed steadily, convenient control, and avoid coking.

4. Cyclone Combustion Technology

Arrange cyclone combustion device in furnace, achieves cyclone fluidized circulating combustion, improve combustion efficiency.

5. Membrane water wall

The furnace, separator and loop seal device adopts membrane water wall, prevents the low efficiency caused by air leakage, low heat loss.

6. Anti wear design

The buried pipe adopts anti-wear steel with the special size and angle, and reduce the fluidization velocity, to reduce the wear. The high temperature resistant material is deposited on the water cooling wall of the separator, avoiding the abrasion of membrane wall.

7. Environment Protection

The product uses low-temperature combustion technology, reduce the generation of noxious gas, also, the limestone could be added to the furnace for desulfuration, meet the requirement of environmental protection.

Steam Boiler

| Model | Steam Capacity (t/h) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) | Design Efficiency (%) | Body Dimension (mm) |

| SHX6-1.25-A II | 6 | 1.25 | 194 | 105 | ≥86 | 9795×7160×13950 |

| SHX8-1.25-A II | 8 | 1.25 | 194 | 105 | ≥86 | 10295×7160×13950 |

| SHX10-1.25-A II | 10 | 1.25 | 194 | 105 | ≥86 | 10795×7160×13950 |

| SHX15-1.25-W+Slag | 15 | 1.25 | 194 | 105 | ≥86 | 10315×8270×14810 |

| SHX20-1.25-AII+Slag | 20 | 1.25 | 194 | 105 | ≥86 | 11565×8570×15500 |

| SHX25-1.25-A II+Slag | 25 | 1.25 | 194 | 105 | ≥86 | 12660×8810×17000 |

| SHX35-1.25-W+Slag | 35 | 1.25 | 194 | 105 | ≥86 | 13350×9880×15800 |

| SHX40-1.25-W+Slag | 40 | 1.25 | 194 | 105 | ≥86 | 14430×9700×15000 |

| SHX50-1.25-A II+Slag | 50 | 1.25 | 194 | 105 | ≥86 | 14430×9630×15765 |

|

Note:1.Parameter is for reference only,we can design the new products based on your requirement. 2. Available fuel: anthracite,bitumite, lignite, lean coal,coal gangue,blended fuel of bitumite and chain slag. |

||||||

Hot Water Boiler

| Model | RatedPower (MW) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) | Design Efficiency (%) | Body Dimension (mm) |

| QXX14-1.25/95/70-A II | 14 | 1.25 | 95 | 70 | ≥86 | 11565×8570×15500 |

| QXX29-1.25/130/70-W | 29 | 1.25 | 130 | 70 | ≥86 | 12930×8280×19800 |

| QXX29-1.6/150/90-H | 29 | 1.6 | 150 | 90 | ≥86 | 12930×8280×19800 |

| QXX46-1.6/130/70-A | 46 | 1.6 | 130 | 70 | ≥86 | 15530×11080×21300 |

| QXX58-1.6/130/70-A | 58 | 1.6 | 130 | 70 | ≥86 | 16240×10600×23500 |

| QXX64-1.6/130/70-A | 64 | 1.6 | 130 | 70 | ≥86% | 17500×11000×24500 |

|

Note: 1.Parameter is for reference only,we can design the new products based on your requirement. 2. Available fuel: anthracite,bitumite,lignite, lean coal,coal gangue,blended fuel of bitumite and chain slag. |

||||||

Power Station Boiler

| Model | Rated Evaporation (t/h) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) | Design Efficiency (%) |

Body Dimension (mm) |

| ZDG-25/3.82-M | 25 | 3.82 | 450 | 105 | ≥ 86 | 12650×8530×13200 |

| ZDG-35/5.29-Q | 35 | 5.29 | 450 | 150 | ≥ 86 | 13350×9880×15800 |

| ZDG-40/3.82-M | 40 | 3.82 | 450 | 105 | ≥ 86 | 14530×10280×18800 |

| ZDG-75/3.82-M | 75 | 3.82 | 450 | 150 | ≥ 86 | 16240×10600×33500 |

| ZDG-130/3.82-M | 130 | 3.82 | 450 | 150 | ≥ 86 | 21060×14400×40650 |

| ZDG - 220/9.8 - M | 220 | 9.8 | 540 | 215 | ≥ 86 | 25540×23420×47800 |

|

Note: 1. Parameter is for reference only, we can design the new products based on your requirement. 2. Available fuel: anthracite, bitumite, Lignite, lean coal, coal gangue, and chain slag, etc. |

||||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.