Biomass Fired Hot Air Boiler

- Rated Power :120~5000kw

- Hot Air Temperature :200-300°C

- Fuel :wood chips, bagasse, straw, olive bone, coconut shell,peanut shell, pellets, rice husk and other biomass fuels

- Application : chemical industries drying, food drying, medicine drying, tobacco drying, ceramics drying, painting drying, dewatering drying, warm house, warm poultry warehouse, drying brick, etc.

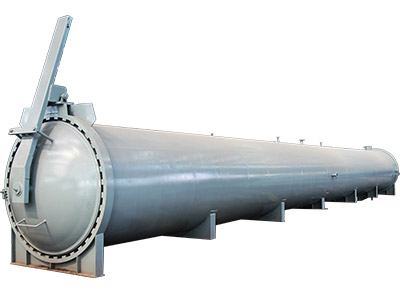

- Brief Intro :WRFL horizontal type hot air boiler proper, it's made up of heat exchanger and moving chain grate, it can be matched with drying system to provide clean hot air.

Email: [email protected]

The arrangement is horizontal and combustion type is mechanical, to reduce labour strength, which can improve combustion efficiency, besides, the design is indirect heating, the characteristic is following: simple structure, high heat exchange efficiency, less dust pollution for heat exchanger, Uniform thermal stress, to avoid dead angle etc.

Hot air boiler whole system is mainly consisted by heat exchanger, moving chain grate, mechanical drive system, combustion furnace, feeding system, slag discharge machine, blower, induced draft fan, cold air fan, Electrically controlled temperature measuring equipment, dust collector and chimeny. With heat exchanger the hot air boiler will generate clean hot air as a dry heat medium, and can be used in different application.

Working Principle

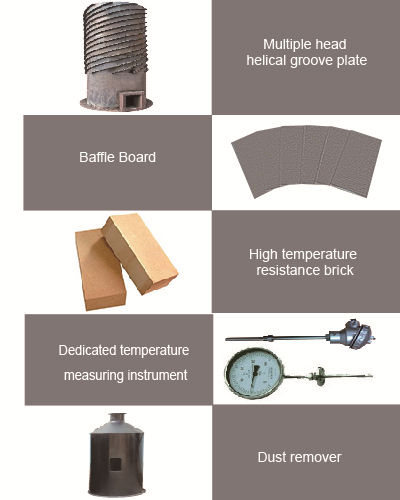

The hot air boiler combustion chamber and heat exchanger in one combined, using the structure of full steel plate multi-layer sleeve type, it's consumption chamber in the below of furnace center, circles heat exchanger in the upper and around, air and flue gas are two-pass, flow separately in heat exchanging. In order to improve thermal efficiency, the multiple head helical groove plate heat exchanging technology and turbulent flow principle, thinning laminar flow thickness, make the air and flue gas constantly exchange revolving on the march, greatly strengthened the heat transfer effect.

The Main Work Process

It produce high temperature flue gas in the furnace by burning biomass, go into smoke ring under the action of fan, and after the heat exchanging with the outside air, through the flue gas ducting and then discharged by chimney, the cold air blow into the shell of the stove by blower, getting into furnace lateral air ring through furnace arch the stove chamber into the lateral air ring, and supply clean hot air equipment by hot air outlet piping.

Advantages

1) Flexibility for various kinds of fuels: Using different types of moving grate can perfectly burn various kinds of fuels, such as biomass shell, bagasse, wood pellets etc.

2) Perfect and complete combustion: customized furnace and primary&secondary air to increase heat efficiency

3) Long life-span: the combustion chamber frame is made by high strength steel and lined by casting heat resistant cement and firebricks. The grate bar is made by heat resistant alloy steel.

4) Automatic operation: fuel feeding, ash discharging and grate moving are automatic.

Parameter

| Name | Rated Thermal Power (MW) (℃) | Thermal Efficiency (%) | Outlet AirTemperature (℃) | Inlet Air Temperature(℃) | ||

| WRF-120 | 0.12 | 72 | 120~150 | -30~25 | ||

| WRF-240 | 0.24 | 72 | 120~150 | -30~25 | ||

| WRF-600 | 0.6 | 72 |

120~150 |

-30~25 | ||

| WRF-2400 | 2.4 | 75 | 120~150 | -30~25 | ||

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||

1. Clean heat energy

1. Clean heat energy

Flue gas and air flow separately for heat exchanging, the heated air is clean.

2. High thermal efficiency

Adopts the multiple head helical groove plate heat exchanging technology and turbulent flow principle, decrease the thickness of laminar flow, to make the air and flow gas exchange heat constantly and revolve during flowing, thus, greatly strengthened the heat transfer efficiency.

3. Wide adaptability of different fuels

The fuel could be coal, wood, straw, bagasse, rice husk, and other biomass fuels.

4. Automatic control

The stove could measure temperature and pressure automatically, convenient for operation.

5. Compact structure, small occupation

The stove has compact structure, it is vertical type, covers small area.

6. Environmental protection

The stove could equipped with dust remover, reduce the dust emission concentration, meet the requirement of environmental protection.

| Name | Rated Thermal Power (MW) (℃) | Thermal Efficiency (%) | Outlet AirTemperature (℃) | Inlet Air Temperature(℃) | ||

| WRF-120 | 0.12 | 72 | 120~150 | -30~25 | ||

| WRF-240 | 0.24 | 72 | 120~150 | -30~25 | ||

| WRF-600 | 0.6 | 72 |

120~150 |

-30~25 | ||

| WRF-2400 | 2.4 | 75 | 120~150 | -30~25 | ||

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.